Fabric manufacturing is a big part of what we do. Not all clothing manufacturers commit to more than pure CMT manufacturing. And many of them source fabrics. Not us. We make them. And in order to make them, we use circular knitting machines.

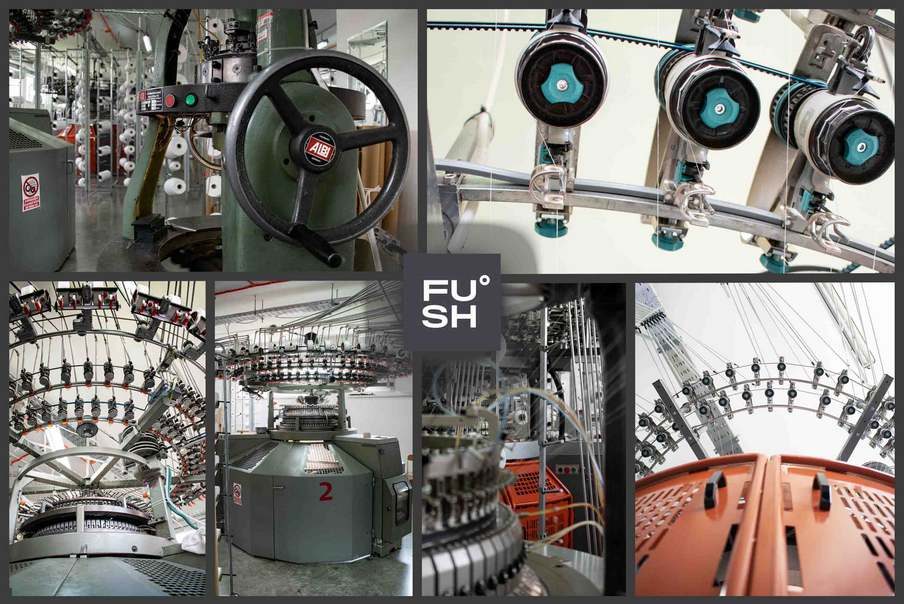

Some of the circular knitting machines you can see if you visit our factory in south-eastern Serbia

They look intriguing, to say the least. Almost as if they came out from a sci-fi movie set. And we’ll try to demystify them in this blog post. First, let us take you through our knitting mill. The video below will walk you through the entire room with all 8 circular knitting machines that we have.

See the video on our Youtube channel – FUSH˚ knitting mill tour.

How do circular knitting machines work?

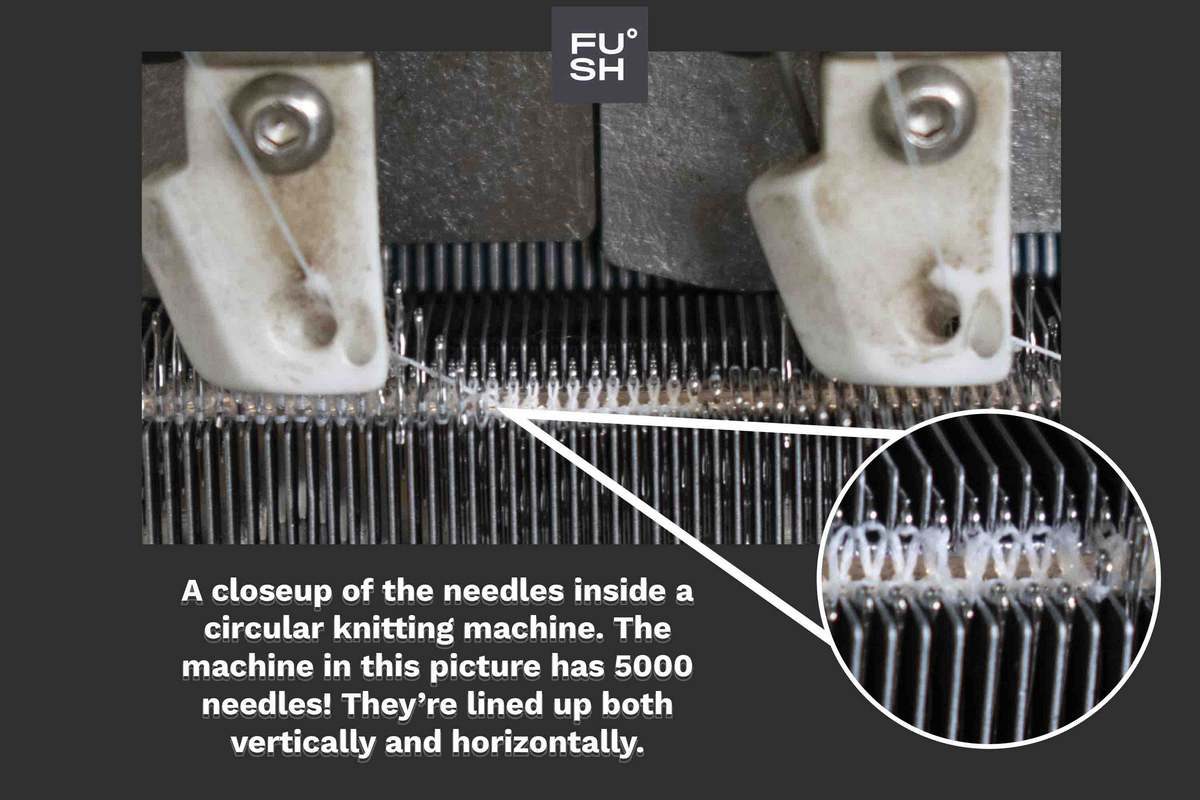

To put it simply, they turn yarn into fabric. A red circular knitting machine you saw in the video has 5000 needles and is capable of making 23 kg of interlock fabric in 8 hours. In the next video, you’ll see how yarn travels from the cone holder to the machine and where it passess through on its way to the needles. You’ll also learn more about the parts of the circular knitting machine.  Youtube video – Circular Knitting Machine (Yarn Journey) So here’s what those parts you saw in the video are used for:

Youtube video – Circular Knitting Machine (Yarn Journey) So here’s what those parts you saw in the video are used for:

- Cotton yarn cones – a spun cotton yarn that feeds the knitting machine.

- Telescopic tubes – guide the yarn in an orderly manner toward the next step.

- Cotton dust – appears whenever cotton yarn is used. That’s why each knitting mill is equipped with air-blow guns (you’ll see a video of our knitting expert Ivica using the air-blow gun to clean the machine).

- Positive feed device – this is a multi-part device that feeds the needles, provides yarn tension, and uses sensors to detect yarn breakage.

- Top and bottom stoppers – it moves upward when yarn breaks, which alerts the sensor and stops the machine.

- Yarn guides – provide yarn tension between the positive feed and the needles.

- Feeder guides – the last stop on yarn’s way to needles and full transformation into the fabric.

- Cylinder – an assembly of needles, cam boxes, cams, and sinkers. Adjusting the cylinders provides different weaving patterns.

- Takedown motion rollers – provide a firm grip on the fabric on its way to the winding fabric roller.

Troubleshooting and maintenance of circular knitting machines

As with anything that has a lot of moving parts, circular knitting machines too can malfunction. Needles can break, yarn can lose tension or it can snap and cotton dust can clog the cylinders or any openings. All of these malfunctions will stop the machine, which is great. Otherwise, the fabric would come out with a completely messed-up weaving pattern. And nobody likes wasted time and materials.

Two videos that you’ll see will show you how we prevent clogging the machine with cotton dust and what happens when yarn breaks.

- YT video – Circular Knitting Machine Troubleshooting

- YT video – Maintenance of Circular Knitting Machines

Finally, let’s see what textures we can make on our circular knitting machines. Thanks to Miroslav, our chief knitting expert, we can make both the standard textures and their variations: single jersey, interlock, rib, milano rib, ottoman, 2-thread fleece, french terry, bird’s eye.

Miroslav’s custom texture is the ultra-light mesh fabric that weighs only 70 grams per square meter (half of the usual fabric weight). Do you want to learn more about our other machinery? Visit our textile machinery page. If your clothing brand needs such fabrics for their clothes, know that there’s a company that both makes the fabrics and the finished product all in one place. And that company is called FUSH˚. Fill out the form below and let us know what we can do for you.

Request a quote from us

To get the best possible price and lead time estimate, please include the number of designs and pieces per design, fabric choice, sizes, and printing options.

- FUSH˚ Addresses:

- Velizara Stankovića 67

Belgrade, Serbia (view in Google Maps) - Oraovačka BB

Oraovica, Serbia (view in Google Maps)

- Velizara Stankovića 67

- Phone: +381 11 359 10 48

- Email: info@fush.rs