At its core, streetwear is about mixing quality, comfort and practicality with self-expression.

The right streetwear manufacturers should be able to create quality clothes that embody comfort, functionality, and self-expression. It’s easy to recognize these three core features of any streetwear piece once you see the finished product. But you, as a sustainable clothing brand, have to find a way to recognize the ability of a custom clothing manufacturer to make such garments.

Here are a couple of clues that can help you learn whether or not a streetwear clothing manufacturer has what it takes to make comfy, practical, and original clothes.

*Minimum order quantity with FUSH˚ is 500 pieces per design/colour. Also, keep in mind that we only work with companies that have VAT and EORI numbers.

Learn more about working with us – visit the what we do page.

How do streetwear clothing suppliers make quality, comfortable clothes?

The answer is simple – they use soft and stretchy materials. Fabrics with a lot of fluff and buttery feel are brushed french terry and fleece. They are the most popular quality fabrics for hoodies and sweatshirts. Great streetwear clothing suppliers should be able to offer your clothing brand those fabrics in many different weights.

These are some of the heavy fabrics readily available at FUSH˚.

The connection between softness and fabric weight

Materials like brushed French terry will pack more of that fluffy inner part as their weight increases. Therefore, the equation is simple – heavier material means more comfort. The most popular fabric weight for hoodies and sweatshirts is 340 gsm but feel free to go higher if the next-to-skin comfort is your goal.

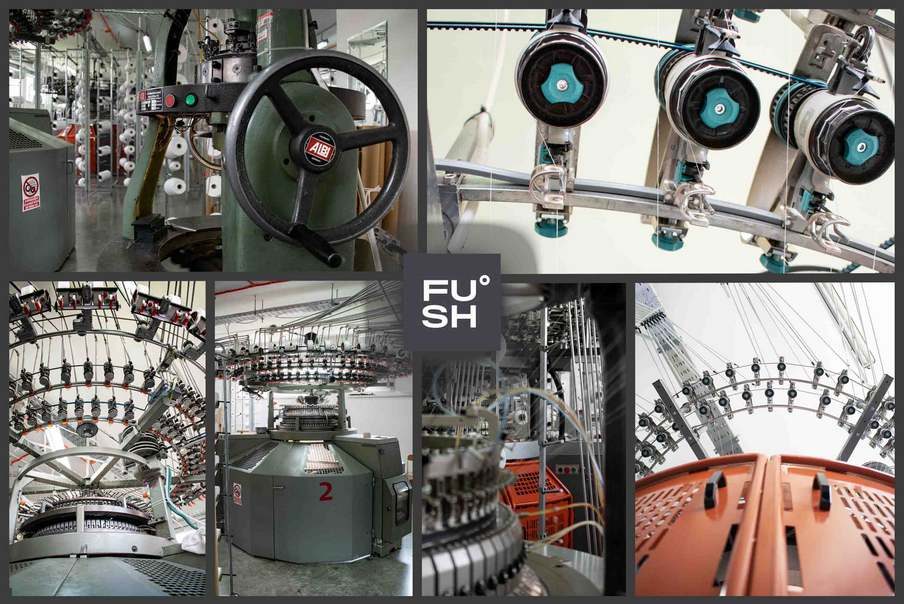

More machines, more customization

The right manufacturer should have many quality fabric options readily available as well as the machinery to process them properly. That means that you should aim for a supplier with a knitting mill.

The reason why we’re able to work with many different, often sustainable clothing brands is that our knitting mill can manufacture high-quality materials for a wide range of clothing items:

- Heavy materials for hoodies and oversized t-shirts

- Light and breathable materials for summer collections

And these are just fabrics relevant to the streetwear market.

Benefits of knitting mills for clothing brands

All clothing brands will benefit from shorter lead times. That’s exactly what you get from streetwear suppliers with a knitting mill. If they run out of stock, they just knit more, which can be done in two shifts. Also, this way, they’re fully in charge of quality control.

This gives you peace of mind in case you sell out your collection sooner than you predicted.

Circular knitting machines at FUSH˚.

Pattern cutting the right way

The thing about 340 gsm soft brush french terry or similar fabric is that it takes up a lot of space on the cutting table. To cut it perfectly, custom clothing suppliers must use CNC fabric cutters.

If they used manual cutters, the bottom layers wouldn’t have the same shape as the top layers. As a result, you might end up with low-quality hoodies that stretch unevenly. And even if you notice the badly cut pieces, you’ll surely lose time waiting for proper replacements to arrive.

A cutter like this can provide perfect precision even with thick layers of heavy fabric.

Add stretchiness for better mobility

If the design of your streetwear piece traces the body even slightly, make sure to ask for materials with elastane. Even 5% of it would improve the mobility and comfort of the people wearing your brand.

Skin-contact area comfort

Whenever you’re sure people will wear your clothes next to their skin, one thing you must insist on is flat seams. The seam is a line where streetwear clothing manufacturers sew together two or more layers of fabric. With special machinery, they can make them flat to prevent chafing and make for high-quality products.

Our seamstresses readily use flatseamer machines to make chafing-free quality clothes.

How do streetwear manufacturers make practical clothes?

The practicality of a streetwear piece can be something as simple as its zippability or pockets of a specific size and position may be connected to practicality too. A weather-resistant jacket as a part of your streetwear brand is also rather practical.

Tech packs as the building blocks of custom styles

To achieve these goals, clothing manufacturers you get in touch with should be able to make custom garments. In other words, they should be able to work off your tech packs. If they only offer white label, template garments, steer clear of them. They probably haven’t set up their production for customization.

The complete customizability of your clothing items will help you establish a better brand identity. Also, it will affect the overall quality because you can target different markets with fine-tuned sizing.

The complete customizability of your clothing items will help you establish a better brand identity.

These are patterns from our modelling department, that is responsible for making customized samples.

How to achieve self-expression with streetwear

Full customization during the garment manufacturing process is necessary for achieving originality. That applies to even seemingly simple products like t-shirts. If clothing manufacturers are to customize garments, they must be able to work off various tech packs, create multiple samples and recreate existing garments. Simple as.

Ask the manufacturers if their sampling department recreates other garments and/or works with clients’ tech packs. If they don’t, they’re not the right fit.

Unless the originality of your streetwear brand focuses on graphics. In that case, other things start to matter more. When you have incredible illustrations that would look great on textiles, then a variety of printing techniques from the manufacturers’ part can play a major role in your quest for brand originality.

Different printing techniques to achieve uniqueness

To get you fully covered, streetwear clothing manufacturers that you plan to work with should offer both screen printing and dye-sublimation printing. We say this because screen printing works better with cotton and natural fibres. On the other hand, dye-sublimation provides the best colour transfer on polyester fibres.

This way, you’ll be able to transfer your graphics and illustrations to any fabric.

Here are examples of sublimation printing and screen printing done at FUSH˚.

What else makes a great streetwear manufacturer?

Other than being able to manufacture comfortable and practical streetwear that stands out in a good way, clothing manufacturers should be ethical, sustainable, and transparent. You can take the easy way and just find the cheapest manufacturer for your clothing brand.

Or you can do the right thing and actually find a factory that ticks all the boxes when it comes to fair working conditions and a positive impact on the environment.

How to spot an ethical streetwear manufacturer

If the manufacturer is really ethical, their workers should have enough free time to have a life outside of work. Regarding compensation, they should be paid at least the national minimum wage of their respective country. Also, they should receive bonus rates for overtime and work during weekends. That’s a bare minimum. You’d be surprised how often this isn’t the case.

FUSH˚ as an ethical business

This is where FUSH˚ as a leading streetwear clothing manufacturer stands out. All our workers:

- Earn at least 20% more than the Serbian national minimum wage

- Work eight-hour shifts

- Receive overtime bonuses (which is a legal requirement often overlooked or misrepresented in the textile industry)

- Receive childbirth, and marriage bonuses (not a legal requirement in Serbia)

On top of all that, we are a Sedex member with a successfully passed 4-pillar social responsibility SMETA audit. This audit is official proof often necessary for cooperation with corporate clients.

How to spot eco-friendly clothing suppliers

Ideally, the manufacturer would have a GRS and/or GOTS certificate, the ISO-14001 standard, and proof of passing the social compliance audit like SMETA. Certificates, standards, and audits guarantee that all the processes in the factory are carried out in a way that’s safe for the environment.

But even without certificates and standards, a streetwear manufacturer should still find a way to stay sustainable. They can handle wastewater safely and handle textile waste so that it doesn’t end up in landfills. Ideally, have an alternative energy source like wind electrical systems or solar panels.

FUSH˚ as an eco-friendly manufacturer

This is another field where we believe what we do stands out from the usual practices in the textile industry because:

- We have the Global Recycled Standard (GRS) certificates for recycled polyester, and the Global Organic Textile Standard (GOTS) certificates for organic cotton

- We have aligned our environmental management system (EMS) with the strict ISO 14001 standard, for which we’re certified

- We handle our wastewater with a certified wastewater system

- We give all our excess textile from the cutting room to a local sports equipment manufacturer that makes boxing bag fillings out of it

- We have a solar power system in our bulk production facility in south-eastern Serbia

Since September 2021, the FUSH˚ factory in Oraovica is solar-powered.

What makes a transparent clothing manufacturer?

There are many garment factories out there with all kinds of social compliance certificates and ISO standards and they still break almost every certification rule. If it weren’t that way, a tragedy like Rana Plaza would have never happened.

Don’t get us wrong, there are clothing factories that deserve all their certification. Such a clothing factory would welcome visitors, be it existing or potential clients.

If a clothing manufacturer you get in touch with acts evasively to the mention of a factory visit, that’s a major red flag and you should run away from them as fast as you can. They’re likely doing something wrong, even if they boast with shiny certificates attached to their name.

Factory visits at FUSH˚

We have five apartments in the factory complex so you could spend days immersing yourself in the clothing manufacturing experience. For those of you eager to visit us this very moment, there’s a virtual tour of our clothing factory in Oraovica, south-eastern Serbia.

Additional perks of working with us

Once we start cooperating, we’d even film the manufacturing process of your product so that your brand can really benefit from the radical transparency which is an ever-growing trend in fashion.

There’s even an option for fashion design services, where we can build your brand from scratch. It comes at a much higher cost, naturally.

Finally, when working with us, your streetwear company is in safe hands because we have extensive experience with casual clothing and streetwear brands.

Conclusion

In order to manufacture high-quality, comfy, practical, and original pieces of streetwear in an ethical and eco-friendly way, the right clothing manufacturer must tick many boxes.

Modern machinery, skilled and well-paid textile experts, sustainable factories, and radical transparency are some of the must-haves for any manufacturer that can actually help your streetwear line outshine other streetwear brands. If they lack one, that’s one too many so brace yourself when you decide to go manufacturer hunting, it might take a while.

Unless you want to give us a try. To do so, fill out the contact form below the FAQ excerpt. If you can, provide as many details about your potential order as possible.

A sneak peek into our streetwear manufacturing capabilities.

FAQ

- What is the cost range for manufacturing streetwear items?

- Are there any specific materials commonly used in streetwear production?

- How do I protect my designs and ideas when working with a manufacturer?

- What challenges do brands often encounter when partnering with streetwear manufacturers?

- Are there any industry standards or certifications I should look for in a streetwear manufacturer?

What is the cost range for manufacturing streetwear items?

It can range from €5.10 to well over 30€ per piece, depending on complexity and quantity. Simple cotton t-shirts of regular 180 GSM* weight with a small print or embroidery can cost around €5.10, while a heavy 400 GSM sweatshirt with an intricate design and a bigger embroidered patch can cost over €30.

The pricing also depends on quantities. At FUSH˚, the €5.10 price point is achievable for orders of 1000 pieces or more.

*GSM means grams per square meter

Are there any specific materials commonly used in streetwear production?

Because the main feature of streetwear is comfort, cotton is the most commonly used material for this type of clothes. Especially heavy cotton (350GSM and above). However, not all cotton is good for streetwear.

A more expensive and an equally comfortable variation would be Tencel and Modal, cellulose-based quality materials that give clothing a silky feel. A halfway point would be a cotton-Tencel blend.

How do I protect my designs and ideas when working with a manufacturer?

Send the manufacturer a non-disclosure agreement (NDA) before sending them your designs or tech packs.

A non-disclosure agreement (NDA) is a promise between two or more parties to keep certain information a secret, in your case, your designs. This prevents manufacturers from using your designs to their own advantage.

It’s best if you get a lawyer to draft an NDA for you rather than making it yourself (unless you are a legal expert).

What challenges do brands often encounter when partnering with streetwear manufacturers?

- Minimum order quantity (MOQs)

- Pricing

- Delivery times

- Quality

In our experience, the main challenge is agreeing on an MOQ. Especially if a brand is a startup. Most manufacturers, especially the cheap overseas ones, demand MOQs of 1000 pieces per design and more.

For the same reason, pricing may be an issue for startups planning to run a high-quality brand. High-quality clothes use expensive materials and processes (mercerisation of cotton, sustainable fabrics like Tencel, etc).

Delivery time discrepancies are another challenge streetwear brands often face with suppliers. This is because most suppliers don’t manufacture fabrics. Instead, they source them, which often prolongs lead times.

Other reasons could be poor time management on the part of the suppliers, especially the ones that offer lower prices. They usually take on more work than they can handle.

If you choose to work with manufacturers that offer almost unrealistically low prices, you’re most likely choosing overworked textile professionals who will make mistakes because they’re at their physical limit. A factory can only make a profit if it overworks its employees in a scenario where it offers low prices.

Are there any industry standards or certifications I should look for in a streetwear manufacturer?

For a streetwear clothing brand, a guarantee that their clothes are made from organic cotton is highly important. That’s why you should start your search for streetwear manufacturers in the certified suppliers database of Global Organic Standard (GOTS). Clothing with the GOTS label is the best way to prove to your customers your clothing is organic.

Another certificate that you can use when labelling your clothes is OEKO-TEX. This one guarantees that no harmful chemicals are used in any stage of making your clothing. It’s easy to check whether or not the label is genuine by visiting OEKO-TEX’s label check page.

For you as a streetwear brand owner who wants to work with well-structured and ecologically conscious custom clothing suppliers, companies holding the following certificates and audit results are the way to go:

- Global Organic Textile Standard (GOTS)

- Global Recycled Standard (GRS)

- 9001:2015 (for quality management), 14001:2015 (for environmental management), and 45001:2018 (for occupational health and safety)

- SMETA audit

Unfortunately, there’s no centralized database for ISO-certified companies.

Request a quote from us

To get the best possible price and lead time estimate, please include the number of designs and pieces per design, fabric choice, sizes, and printing options.

- FUSH˚ Addresses:

- Velizara Stankovića 67

Belgrade, Serbia (view in Google Maps) - Oraovačka BB

Oraovica, Serbia (view in Google Maps)

- Velizara Stankovića 67

- Phone: +381 11 359 10 48

- Email: info@fush.rs