Sublimation clothing can be explained in a couple of ways. We’ll cover all possible definitions in the following segments. Keep on reading and you will find answers to the following questions (and some more):

- What is sublimation clothing?

- How does sublimation printing work?

- Is sublimation printing eco-friendly?

- Can you sublimate on recycled polyester?

- How can dye sublimation replace dyeing?

- Sublimation benefits and drawbacks

- Dye sublimation problems and solutions

- Which one is better – sublimation or screen printing?

- How can I order dye sublimation clothing from FUSH˚?

Learn more about working with us – visit the what we do page.

What is sublimation clothing?

Sublimation is what happens when dye transfers from paper to fabric under heat (between 170° C and 210° C). Sublimation clothing is what you make from such fabrics. Unlike other types of printing, sublimation printing makes sublimation clothing more breathable and with better colour retention.

It gets its name because the term sublimation represents a direct switch of state from solid to gas without switching to liquid beforehand. With sublimation clothing, what changes the state is the dye-sublimation ink. It’s solid on paper, gaseous when travelling from paper to the fabric, and finally solid again, once the fibres absorb it. Now let’s learn how and where that switch happens.

How does sublimation printing work?

Now that you know what sublimation is and what sublimation clothing is, let’s learn how it happens in real life, not just in theory.

For sublimation printing to work, you need to have:

- A design you want to print

- Dye-sublimation printer

- Dye-sub paper

- Protection paper

- Calender heat press

- Fabric fit for sublimation

Dye sublimation printers

They’re special types of printers that can usually hold rolls of paper weighing up to 45 kg, which is great for mass production. But inkjet printers can do that too. So what’s the difference?

They’re different from inkjet printers because instead of spraying the ink droplets onto the paper, they heat the solid sublimation ink and sublimate it onto the paper. So, the first case of ink sublimation happens in the printer. The great thing about sublimation inks is that they’re water-based and therefore 100% eco-friendly.

Dye-sub paper

A special type of ink needs a special type of paper to make things work. Dye-sub paper is special because its coating prevents the ink from becoming liquid and allows for the sublimation process to happen. This ensures the final result is a crisp image on the garment with no colour smudges.

If you were to try doing this with regular paper, you wouldn’t be able to achieve a direct switch between solid and gas states. And with that, you’d risk bleeding the image and messing up your design in general.

Calender heat press

You need high heat in order to transfer the ink from paper to textile, right? Well, to make it happen, you need a machine that will roll both the paper and the material as well as expose them to temperatures between 175 and 230°C.

A calender heat press is a machine that does all that. It even does roll-on-roll sublimation. This means you will end up with rolls of fabric with designs already applied to them. All that’s left in that case is to cut and sew it.

The image below shows the more typical case of dye sublimation – sublimating the pre-cut fabrics.

The calenders we use are products of Italian manufacturer Monti Antonio, who is touted as the best in the industry.

Fabric for sublimation clothing

Polyester, both recycled and virgin, perform the best when sublimated. When exposed to heat, the pores in fibres open and soak up all the ink perfectly. Once it’s out of the heat press, the ink becomes one with the fibres and there’s no way you can wash it away.

That’s not the case with natural fibres like cotton or synthetic fibres like polyamide. These fabrics don’t retain the ink well and fade over time.

In order to repeat the same shades and colours, a company that would do dye-sublimation for you should either:

- Have the same fabrics available all the time

- To be a fabric manufacturer too

Is sublimation printing eco-friendly?

The process alone is 100% eco-friendly. It can even replace traditional dyeing methods that consume too much water. And that means that instead of wasting hundreds of litres of water just to dye one t-shirt, you’ll use 5ml of sublimation ink to achieve the same result.

Second, the ink is water-based and contains no harmful substances. The only waste that this process generates is 100% recyclable sublimation paper.

To make sublimation more eco-friendly, you should ask your clothing manufacturer(s) to use unbleached polyester yarns to make the fabrics as well as to avoid bleaching. Keep in mind that the white colour from your design will be slightly off in the final product. But if you don’t use big patches of white, it will be barely noticeable and you would be good to go.

Can you sublimate on recycled polyester?

Of course you can. When it comes to dye sublimation printing, recycled polyester is not too different from virgin one. On a microscopic level, the fibres are a bit rougher which is actually better for moisture-wicking. But as far as ink retention is concerned, there’s absolutely no difference between the two types of polyester. In fact, we strongly advise you to sublimate rPET fabrics precisely for the reason of using the full ecological potential of this printing technique.

Certified recycled polyester

We advise using recycled polyester for another reason – we can make officially GRS-certified polyester clothing, which means you can have a hang tag on your collections showing they’re made from genuinely recycled materials. This is something your customers can see when they pick up your clothing off the rack. Give FUSH˚ a shot as your GRS clothing manufacturer, we’re certified.

Social responsible textile sublimation

It will soon become a legal obligation to work with manufacturers that have a way of proving their business is a socially responsible. The easiest way to find one is to become a Sedex member and find manufacturers that have passed the SMETA 4-pillar social responsibility audit.

Before we passed it, we had (and still do) an open factory visit invitation to existing and potential clients. To that end, we have fully furnished five apartments at the factory grounds of our mass production facility.

How can dye sublimation replace dyeing?

If you need plain-coloured polyester t-shirts, you won’t need to send them to a dyeing mill. Instead, you can find a clothing manufacturer that does dye sublimation printing. A printable vector file with just one colour in it is all it takes to make this happen. This is a significantly more affordable and sustainable way to apply colour to a man-made fabric.

Sublimation printing – benefits

- Unparalleled colour retention

- Uninterrupted breathability

- Greater comfort

- No limits when it comes to design (perfect for making standout t-shirts)

Let’s see the reasoning behind each of these benefits. If you already know the benefits, go straight to the drawbacks.

Best colour retention

Because of the way ink penetrates the polyester fibres when sublimated, colour retention of dye sublimation can easily last up to 10 years! Long-lasting clothing is something every sustainable brand strives for.

And because the dye is transferred IN the fabric rather than ON it, the print will never crack. And the colours alone are very vibrant, being that sublimation printers use the CMYK inks, which allow the best colour range.

If your streetwear brand achieves its uniqueness through graphic design more than the garment design itself, this printing technique is ideal for you.

Of course, sublimation has its limits and only works well when using polyester, as we said before.

Uninterrupted breathability

Compared to other printing methods, dye sublimation doesn’t obstruct the airflow nor the moisture-wicking properties of polyester fabric because it’s not a layer of dye slapped across the material. It’s a way to make the dye one with the fibre. So if you are interested in starting an activewear brand, you organize marathons, cycling races, or triathlons, dye sublimation is your “lord and saviour”.

It’s fantastic that there’s a printing method that allows you to highlight your events’ sponsors or your sportswear brands’ creative design while maintaining the full breathability of the clothing. That method is dye sublimation printing, long may it live.

Dye sublimation = more comfort

Because the dye is in the fibres and not on their surface, you won’t feel like you’re carrying something on your t-shirt. This can be the case with heat press-printed or screen-printed garments. For the same reason, dye sublimation prints won’t increase the stickiness of your clothes, so more comfort there.

Limitless design opportunities

There are more reasons for this. As we said before, dye sublimation uses the CMYK inks, which means all colours are available, Pantone included. From early 2020, even fluorescent colours are available.

Then, because sublimation calenders are wide enough to transfer the design on bigger surfaces, you can use dye sublimation for banners and flags too.

Sublimation printing – drawbacks

Of course that not everything is peachy in the world of sublimation clothing. Of course, it has its limits.

- It only works well with polyester fabrics

- It’s not as cost-effective for bulk orders as other printing methods

- The base fabric should be light-coloured otherwise say bye-bye to unparalleled vibrance

- It fades quicker if exposed to direct sunlight too often

Polyester-only partyPolyester is the sole beneficiary of this printing method because natural fibres don’t respond well to man-made inks, man-made fabrics do. |

Awesomeness comes at a priceDye sublimation is the most expensive printing method so if its benefits don’t align with your brand’s goals, then you would probably do better with digital printing or screen printing for bulk orders. |

Light-coloured fabric mandatoryBecause what gets transferred is the ink, it can only happen on light-coloured materials. It’s as if you tried to write with a pink sharpie on black paper, you wouldn’t end up seeing the writing quite clearly. |

UV Lights – sublimation’s kryptoniteEven though dye sublimation can do so many things, it can’t stand the direct sunlight. On the upper hand, it would take quite a long time for the print to fade noticeably, even if constantly exposed to UV lighting. This one is more of a theoretical drawback than a real-life one. |

Dye sublimation printing: problems and solutions

Like any process in any profession, dye sublimation comes with its own set of issues that you should know how to handle. Below are the ones we have encountered so far:

- Fabric shrinkage

- Ink bleeding

- Bleeding after thermofixing and related issues

- Issues with protection paper

- Design limitations with dye sublimation

Fabric shrinkage

Fabric shrinkage is a common issue for fabrics that aren’t thermofixed. This is why printing departments always run a test sample to track potential errors. If shrinking occurs, these are the steps to follow:

- Measure the shrinking percentage

- Notify the pattern makers and designers and request from them to scale up the patterns and designs by the same percentage the fabric shrinks at

- Run another test, measure, and if everything is as per tech pack, move on to mass production

For the most part, this would be enough. However, another issue might happen with specific fabrics – the bleeding effect.

Ink bleeding during sublimation

Scaled patterns and designs can’t fix a bleeding image – when a colour goes over the edge of a shape in a way that resembles watercolour.

That usually happens near the edges of the fabric that passes through the calender, so the only solution here is to run the entire fabric roll through the calender before printing. The standard temperature of this process is 205 °C. This way, you get a thermofixed and stabilized fabric that retains the ink as intended.

Materials like microfibre lycra and elastic bands must go through thermofixing before sublimation. However, sometimes even thermofixed materials cause problems.

Issues with protection paper

Dye sublimation isn’t a complete process if there’s no protection paper. You must use it to ensure:

- The fabric doesn’t get damaged or stained

- Excess ink doesn’t end up on the calender belt

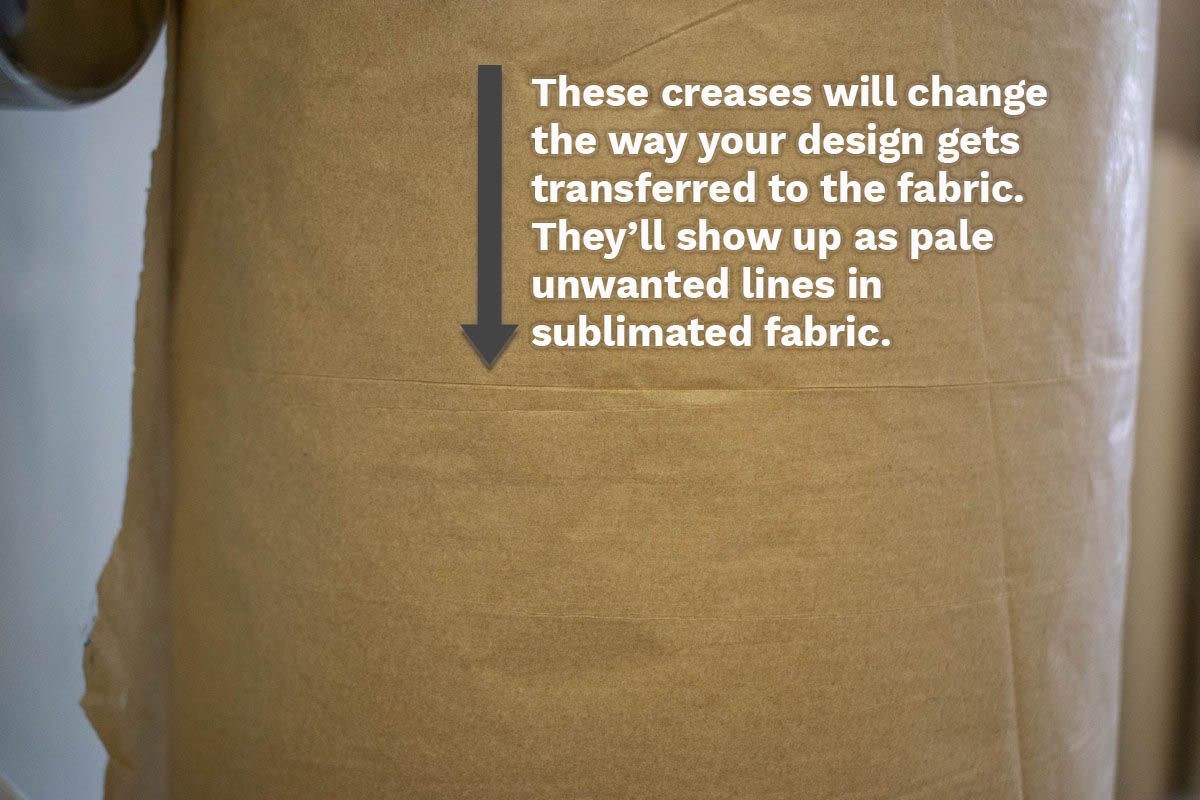

However, this paper can cause you headaches. The roll can have tiny creases you might not spot when you mount it on the calender, and those creases might show up on the fabric as unwanted white lines. That indicates that you’ll have to inspect or completely change the roll.

The paper can also tear and stay on the calender drum, which results in a paler print in the place where fabric made contact with that torn piece.

If your dye sublimation team regularly checks paper rolls, batches and machinery, problems with protection paper will be insignificant.

Design limitations with dye sublimation

Some problems that stem from designs themselves.

The most common issue here is when a design consists of light-coloured thin lines and tiny fonts on dark-coloured backgrounds. More often than not, these lines and fonts will disappear in the ridges of the fabric’s knitting pattern (single jersey is a good example).

Dye sublimation vs screen printing

From what you’ve read so far, you’d probably be able to name a few advantages for each printing method. Now let’s see how they compare against each other a bit more in-depth.

Round 1 – small batches

It takes the same time to set up the screen printing process for 1 t-shirt and 1000 t-shirts. There are a lot of steps you should take to prepare for screen printing: design and screen preparations, aligning the acetate paper with the design, ink curing, and test prints. It takes time, effort, and material to do it. And it all comes at cost, much higher than what it would come when doing the same amounts with dye sublimation.

In contrast, you can print as little as one t-shirt with dye sublimation at a much lower cost because prep time is insignificant and the only expense is electricity that you’d use when turning on the calender.

Result: Dye-sublimation wins.

Round 2 – fabric variety

By now, you should know that sublimation printing only works well with polyester fabrics. However, screen printing has no such limitations. Cotton, poly-cotton, tencel, polyester, you name it. Regardless of what textile you print on, quality and durability won’t change.

Result: Screen printing wins.

Round 3 – durability of the print

Since screen printing binds the dyes to the surface of the garment, it’s only natural that it will be more susceptible to damage and therefore be less durable. Since dye sublimation gets its inks deep into the fibres’ pores, it will last much longer than screen printing.

Result: Dye sublimation takes the lead.

Round 4 – time consumption

With dye sublimation, setup is super-easy. Just ensure your printers have ink, click print and wait. Industrial printers can print 50 square meters in 60 seconds, so the wait is insignificant. Then the rolls of paper and the fabrics go onto calender heat press that takes one minute to transfer the ink on up to 1 meter of fabric. As far as design complexity goes (more colours, gradients, etc), it takes up the same amount of time to get the final product out.

Screen printing setup is quite time-consuming, especially when it comes to more colours or gradients. In fact, you’d have to go through extra work just to prepare the design if you were to screen print gradients. Even the most basic design would still take more time to prepare, but as soon as more colorus are involved, get ready to spend a lot more time preparing.

The printing process itself is where screen printing shines. After you’ve laboured to set it up, it will reward you with a streamlined printing process that actually beats sublimation printing.

There’s no real winner here because it would all depend on the volume of work and the complexity of the design.

Result: draw.

Round 5 – cost-efficiency

As soon as production volume nears 100 pieces, screen printing is the more cost-effective option. The machinery doesn’t cost as much, the raw materials as well. It comes with some quality issues when compared to sublimation printing but only in the case of polyester clothing. Also, you can screen print manually if you really need to.

For dye sublimation printing, you need a printer and a calender heat press, you don’t have the flexibility when it comes to types of materials, and it also takes longer to finish higher volumes of orders.

Result: screen printing wins

Sublimation vs screen printing – conclusion

It’s safe to conclude that there’s no one answer. Depending on your needs, one or the other would be a better choice. Each comes with benefits and drawbacks.

How can I order sublimation clothing from FUSH˚?

The best way to order is to fill out our contact form at the bottom of the page. Here’s what you can write in order to get the best possible price estimate:

- Let us know what type of sublimated clothing you need (sublimated t-shirts, leggings, sports jerseys, tracksuits, sweatshirts, sweatsuits, jackets, vests, tops, sports bras, aprons, flags, banners, or something else)

- Send us your design(s)

- Clearly position the logos and other design features on the technical drawing of the garment (this is a must-have)

- Send us your pattern (s)

- Write your fabric preference (virgin polyester, recycled polyester)

- Let us know what amounts you want us to make

- Write what city should the goods be shipped to (we can deliver new clients’ orders personally if their address is near our regular clients’ cities)

It is possible that you won’t have your own patterns. In that case, you can take a look at our catalogue and if the shape of any garment you see there looks like something that can represent your brand, we can make a pattern just like that one and make a sample piece accordingly.

Our minimums are usually 500 pieces per design but for sublimation clothing we can make exceptions and we could offer lower moq.

Either way, you’d have to be a registered company with valid VAT and EORI numbers if we are to coopearte.

Want to see how our dye-sublimation department looks like? Go on a virtual tour and find out.

FAQ

What is the best material for sublimation shirts?

100% polyester is by far the best material for sublimation t-shirts.

It’s better than natural fibres because it absorbs more of the ink and does so on a molecular level, so it’s impossible to wash it off. It’s better than other synthetic fibres because, unlike polyamide and nylon, it doesn’t melt under temperatures of 170° C and higher.

What t-shirts are best for sublimation printing?

Plain white 100% polyester t-shirts are best for sublimation printing for one and only reason – you can’t print white colour with dye sublimation printers. A white t-shirt is a guarantee that you’d be able to use that colour in your design.

Also, the t-shirt must be 100% polyester if you are to effectively use it for dye sublimation. That’s the only fabric that absorbs the ink well and doesn’t melt or shrink excessively under temperatures necessary for dye sublimation (170° C – 230° C).

Will sublimation stay on 100% cotton?

No it won’t. Natural fibres can’t absorb sublimation well enough.

Also, the colours fade increasingly after each wash. There is a workaround – a polyester coating that you spray onto the fabric before sublimating. However, it too will eventually wash away and you’ll end up with a pale print that looks bad. Stick to polyester if you are to use dye sublimation.

Now that you have all this information, waste no time and send us that enquiry.

Request a quote from us

To get the best possible price and lead time estimate, please include the number of designs and pieces per design, fabric choice, sizes, and printing options.

- FUSH˚ Addresses:

- Velizara Stankovića 67

Belgrade, Serbia (view in Google Maps) - Oraovačka BB

Oraovica, Serbia (view in Google Maps)

- Velizara Stankovića 67

- Phone: +381 11 359 10 48

- Email: info@fush.rs