What does that mean? It means that a clothing brand that wants as much control over its product as possible should rely on a clothing factory with all production done under one roof, especially fabrics manufacturing.

Quality must be a constant

Not all suppliers include fabric knitting in their cut and sew apparel manufacturing. They will often get their fabric from external sources. And those sources aren’t under your watchful eye as a clothing brand. That means the fabric quality can vary. As a result of relying on such a supplier, you risk having different yarns on seemingly the same pieces of clothes. That can affect their performance, which leads to bad reviews by your customers.

Same yarns, same quality

When your clothing line suppliers have knitting facilities, fabric quality CAN be consistent. You know your clothes’ entire production is made in one place and from the same yarns. And equally important, by the same people who know what you would expect.

Such a clothing factory has room for innovation

Working with a clothing factory with knitting capacities comes with more perks. If they tinker with different knitting patterns long enough, they might find a way to make higher-performing fabrics.

Our knitting expert Miroslav Ristić created an ultra-light mesh fabric that weighs half the weight of a regular running shirt fabric. It made its way onto a running tee you can see in the image and the video below. That‘s an S-sized technical t-shirt weighing 50 grams!

The ability to knit our own fabrics brought about fantastic cooperation with a local running community – BRC (Belgrade Running Club). We were helping them build their own running wear clothing line from scratch. And the brand-building involved a lot of testing with different knitting patterns. Something that can‘t be done quickly unless a manufacturer doesn‘t have their own knitting machinery.

Faster turnaround

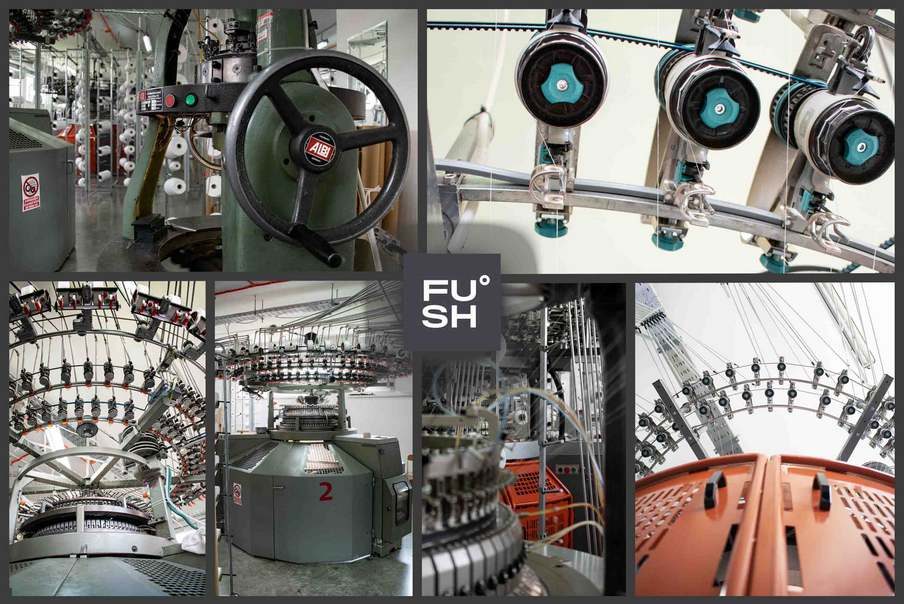

FUSH˚ as both a clothing and fabrics manufacturer has the advantage of not relying on a 3rd party for fabrics. And having 8 circular knitting machines, we are capable of knitting differently-patterned fabrics for large batches of orders. To illustrate it more clearly, here‘s an estimate. If all 8 machines were to make one pattern for 8 hours, they would knit a total of 2.5 tonnes of fabric in one day. So if they were to knit a different pattern each, each would knit 312.5 kg of fabrics in a day. That‘s enough fabric to make around 2400 t-shirts in 8 patterns. Now that seems like a respectable yield, wouldn‘t you agree?

Milovan Ristić tending to a circular knitting machine. Having said all that, purchasing only fabrics from us is a possibility. The fabrics we have made so far are from cotton, polyester, lycra, linen, and bamboo yarns. Get to know us better on the following pages :

Send us your enquiry, fill out the brief contact form below.

Request a quote from us

To get the best possible price and lead time estimate, please include the number of designs and pieces per design, fabric choice, sizes, and printing options.

- FUSH˚ Addresses:

- Velizara Stankovića 67

Belgrade, Serbia (view in Google Maps) - Oraovačka BB

Oraovica, Serbia (view in Google Maps)

- Velizara Stankovića 67

- Phone: +381 11 359 10 48

- Email: info@fush.rs